OCTOBER 15, 2021 | OEE MONITORING IN MANUFACTUING:WHY IS IT IMPORTANT, WHAT ARE THE OPPORTUNITES AND CHALLENGES

Have you ever wondered if your machinery is operating at its full load capacity? Or perhaps you’ve seen numerous time losses in your equipment during various operations, resulting in a reduction of overall output but you can’t seem to find the source of the problem. A situation like this is precisely why overall equipment effectiveness helps solve and correct.

The term overall equipment effectiveness (OEE) is used to evaluate how efficiently a manufacturer’s operation is being used. OEE helps you identify the problems in your operations and determine which percentage of production time is truly productive and repair it while providing a consistent measure for measuring progress. Moreover, continuous improvement is the objective of measuring your OEE.

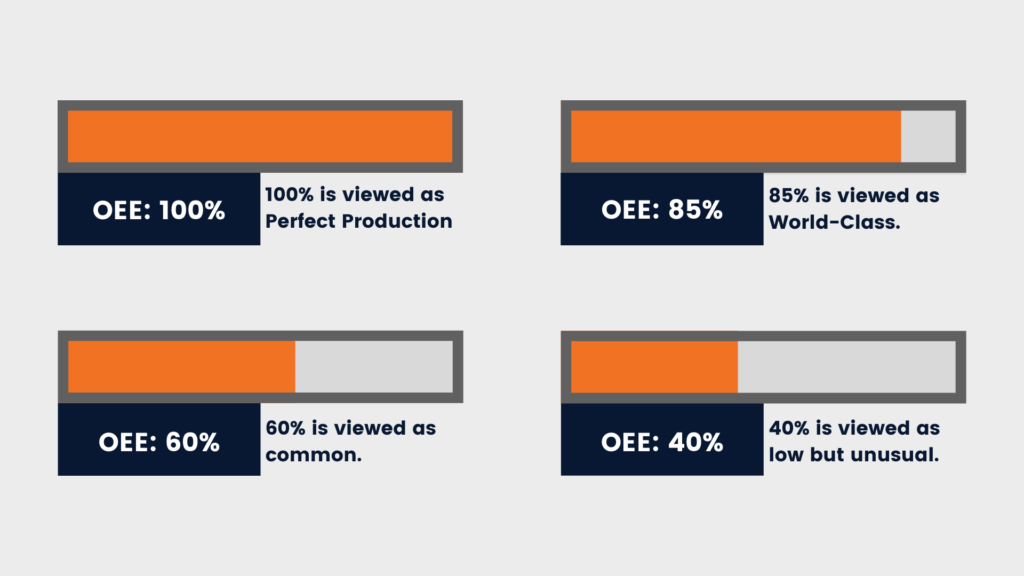

OEE is an important measuring tool that provides a lot of information in a single figure and there are multiple ways of measuring manufacturing productivity from OEE. When OEE is measured and evaluated correctly, it has the potential to maximize your production. The benchmark of OEE is used to compare any given production to industry standards and in-house equipment. The standard OEE benchmark is measured as follows:

- Perfect production is defined as an OEE score of 100 percent, which means you’re only producing high-quality components as rapidly as possible with no downtime.

- For discrete manufacturers, an OEE score of 85 percent is considered world-class and is a long-term objective.

- A 60 percent OEE score is common for discrete manufacturers, indicating that there is still a lot of opportunity for development.

- An OEE score of 40 percent is considered poor, but it’s not unusual for manufacturers that are just getting started with performance tracking and improvement. In most situations, a poor score may be readily improved by using simple steps.

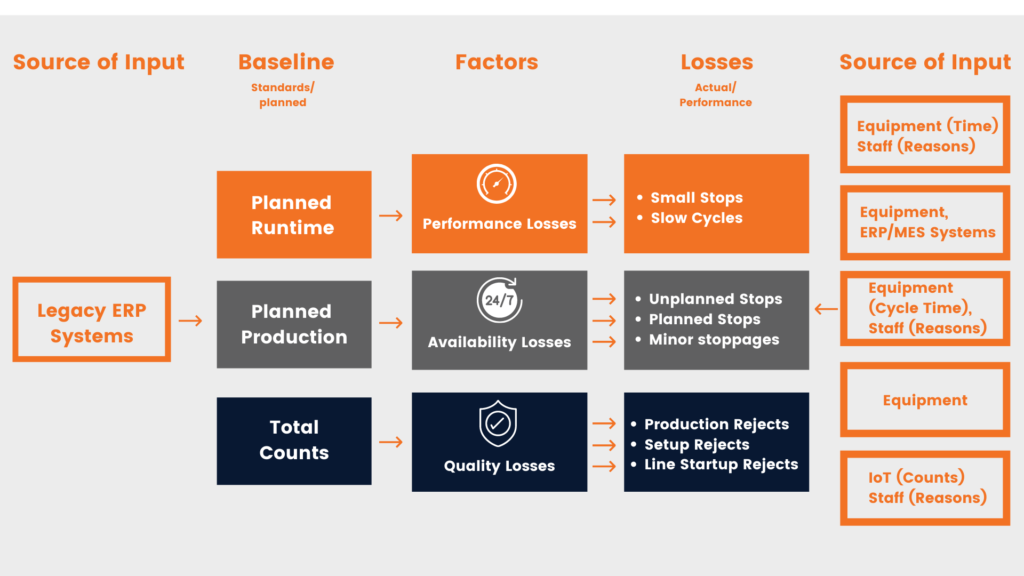

Continuously measuring OEE requires you to obtain different sources in different times frame such as connectivity between different management systems (ERP, MES), equipment sets, IoT devices and staff reporting (tablets, screens).

With production line producing more than one product, it makes sense to manage OEE in the context of the specific product and specification which correlates to the two key OEE parameters, Availability and Efficiency.

Opportunities

- By using OEE management, data collection is more accurate than manually inputting on a spreadsheet.

- OEE can be an important tool in balancing tasks and responsibilities in your manufacturing

- OEE can help you understand how to increase profit through increased Availability

Challenges

- It is easy to collect any data of machine faulty but when there’s too much data, it becomes a mess that makes it difficult to identify the real issue. Collect less data, do it effectively, and then make judgments based on that data. The value of data is determined by how it is applied.

- Human interpretation still needs to remain in the core element of OEE study and calculation. When a machine goes down, part of the line control system (the data collecting software) should be able to immediately tell the status change, but this is not always the case. This is where we need to validate the data and correct the software setup which requires humans to collect the data and understanding the contributing factors behind the numbers.

Benefits of using Overall Equipment Effectiveness (OEE) to improve production

Implementing an overall equipment effectiveness strategy can help you meet your production goals. It enables you to fine-tune production processes in real-time, decreasing downtime, boosting capacity, lowering cost, enhancing the quality, and increasing efficiency.

- Return of Investment (ROI): Your company heavily invests in machinery, and it is crucial to receive the maximum return of investment. When using the OEE strategy, it may have a significant impact on your bottom line by producing more products on the same equipment at the same time.

- Maximize Workforce Productivity: OEE can help you figure out why you experience operator downtimes, provide productivity statistics, and highlight delayed changeovers or setup times. This type of information helps in resource allocation, identifying areas of surplus capacity and determining where additional personnel are required.

- Easily Visualize Performances: Overall equipment effectiveness focuses on visibility, allowing you to visualize production difficulties rather than relying on your best estimate. Everyone can see what is working and where improvements are required by combining the major drivers of productivity losses into a single percentage.