Embrace The Industrial 4.0 Revolution & Prepare To Welcome The Future

Tanand’s APD system brings production efficiency and improve yield by providing real-time drying performance and drying end time prediction for paddy through integration with IoT sensors and Big Data Analytics.

Tanand is the pioneer in bringing IoT technology to rice industry and we own the patent for paddy moisture content prediction algorithm & methodology. With that, our APD can improve your grain quality from using either inclined bed dryers (IBD) or mixed flow dryers. Start your journey of improving your yield with automated control & monitoring with us now!

Common Rice Industry Problems

|

Manual operation

|

|

Poor working condition

|

|

High risk of faulty

|

How We Automate Your System

Optimize Drying AI

|

|

Remote temperature

|

|

Grain moisture content predictionPatented paddy moisture content prediction algorithm with >95% accuracy improves productivity and revolutionize the paddy drying process. |

Powerful cloud systemPowerful processing capability to process and analyze the input data with real-time web & mobile app centralized dashboard for performance monitoring & control. |

|

Big Data analysisVisible dryer performances and grain data in real-time are the keys for future improvement. Collected data will be benchmarked for future analysis and AI will constantly learn and improve the algorithm accuracy to optimize the drying performance. |

|

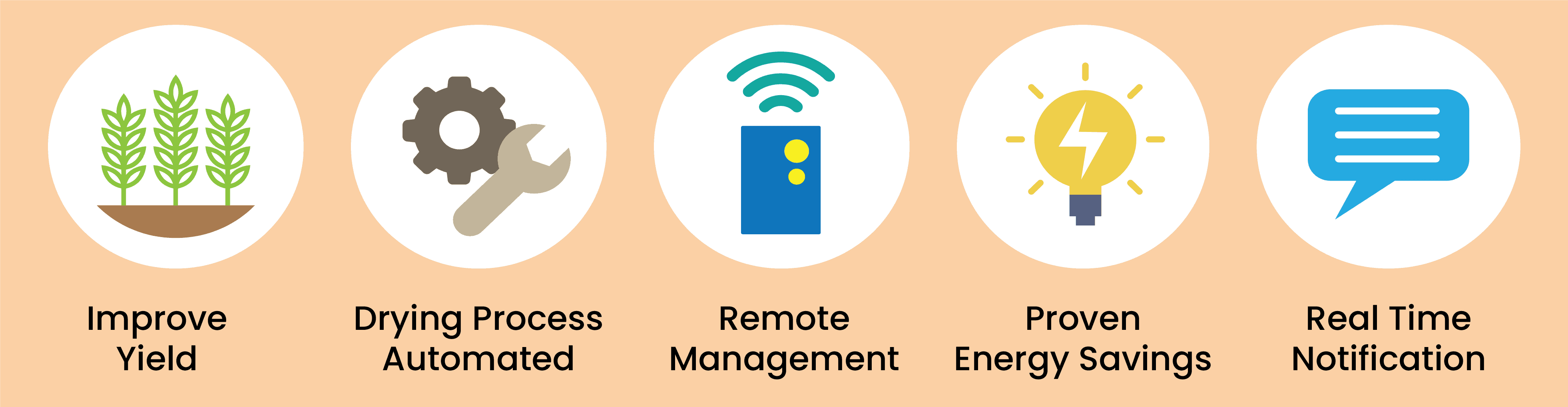

Benefits & Results You Will Get

- Minimize the stress/broken rice

- Increase plant profitability by reducing cost and improving yield with measurable results

- Automated monitoring and control of conventional paddy drying system

- Optimized drying capacity with the integration of wireless smart sensors, IoT gateway, and Big Data

- Multi-branch monitoring by using cloud computing

- Reduce electricity consumption

- Predictive maintenance feature with real-time alert notification

- Real-time dryers data for KPI setting and continuous improvements

Our Success Stories

Advanced Paddy Dryer (APD) Lite

- Industrial 4.0 cloud-based computing remote smart web & app

- Boiler & dryer real-time monitoring & adjustment

- Instant notification when boiler & dryer running in non-optimal condition

- Never miss an important operating condition that affection production & quality