Overall Equipment Effectiveness (OEE)

In today’s competitive manufacturing landscape, by measuring efficiencies and productivity across machines, lines, or individuals, OEE provides a comprehensive assessment of production effectiveness, serving as a cornerstone for continuous improvement initiatives.

Moreover, real-time production line monitoring has revolutionized how manufacturers oversee their operations. In the past, monitoring production lines relied on dedicated personnel, offering a limited view of potential issues. However, with advanced production monitoring systems, manufacturers gain real-time visibility into their entire facility. This enables them to identify best practices, minimize downtime, and pinpoint areas for enhancement swiftly. The availability of real-time data empowers managers to make informed decisions promptly, driving operational excellence and competitiveness in the market.

Challenges in Implementing OEE Systems

Many manufacturing facilities find themselves relying on antiquated business metrics that do not effectively depict the performance of their production assets. However, opting for an unsuitable OEE system in your manufacturing process can result in a range of issues.

Common challenges faced during the implementation of alternative OEE systems include:

Integration Hurdles

Integrating machine data across your factory proves challenging with alternative OEE systems.

Complex Setup

OEE Systems in the market are complicated to set up and install.

Manual Records

Low performance and production analytics to predict task delivery time.

Lack of Visualisation

Operators could not identify production bottlenecks & improve production.

OEE Solution For Your Production Monitoring

Whether you operate a small manufacturing facility or are a globally recognized enterprise, implementing Tanand Easi OEE monitoring offers numerous practical benefits for your business.

No PLC or SCADA Integration

No requirement for PLC or SCADA integration.

No Server Maintenance

No necessity for server maintenance.

Software Upgrades

Enjoy limitless software feature upgrades, with over 14 enhancements provided within a three-year period at no additional cost.

Good REST API

Seamless integration into your current ERP system is facilitated through a well-developed REST API.

No Installation

No installation of software required.

Alert Notifications

Immediate alert notifications delivered via WhatsApp/Telegram.

Standalone IoT

Functions independently as a standalone IoT.

User-friendly

Designed to be foreign-worker-friendly—simply pick up the scanner and scan the cause when production experiences slowdowns or downtime.

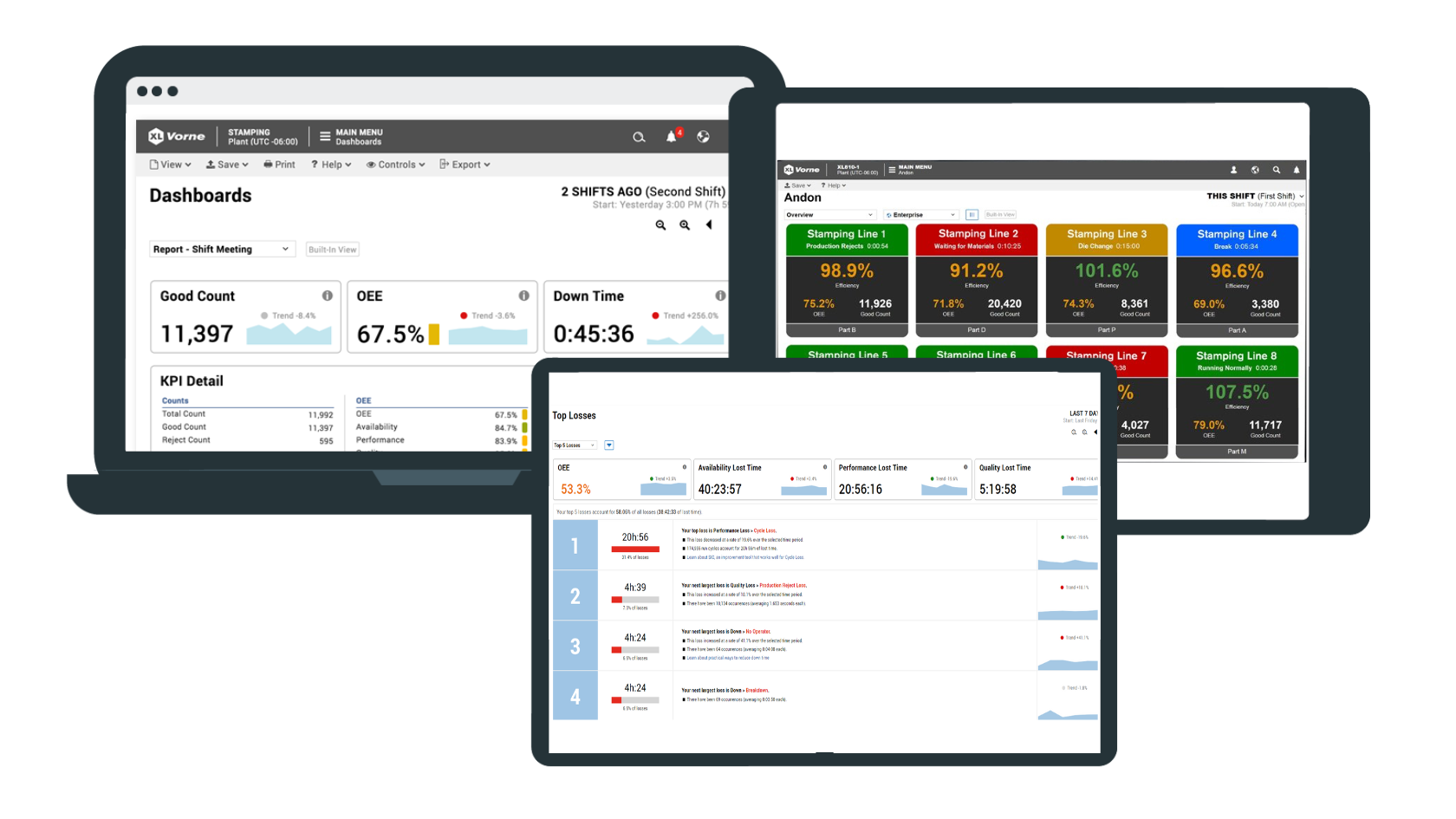

Real-Time Production Monitoring

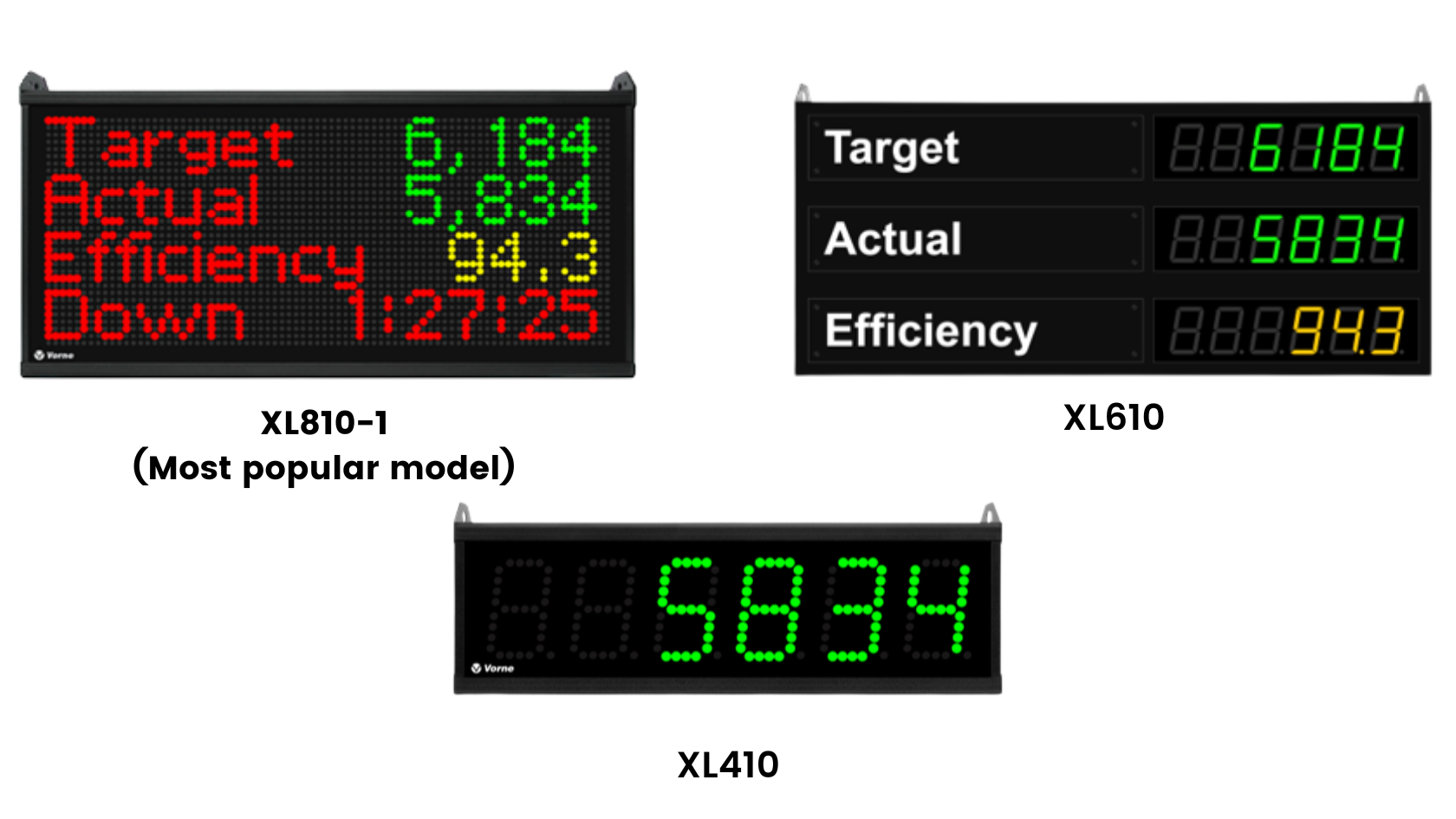

Leveraging over two decades of expertise in enhancing OEE for manufacturers, Vorne XL offers straightforward integration into your production floor. Accessible through a web browser, it provides a real-time production dashboard and a user-friendly scoreboard with eight configurable metrics, ensuring immediate visibility into your production processes.

The scoreboard display serves as a straightforward visual communication tool, promoting motivation within the production team through transparent data presentation.

Point-and-click to create your own detailed analytics report:

- Personalize each view to visualize whatever is most important to your team

- Incorporate table, chart, chronogram, KPI, and KPI group widgets

- Instantly export any table to Excel

- Exactly what you want to see, exactly how you want to see it

Motivate the Production Team & Let Them Win The Shift

Utilizing Vorne XL’s interactive, robust, and industrial-grade real-time scoreboard, production teams can effortlessly track their real-time performance. With XL, flexible targets for daily, weekly, and monthly objectives can be set, offering various incentives upon achieving these goals. Transform your production team into a highly motivated unit, fostering competition to reach new targets set by the management team.

Accurately Capture Downtime & Performance Reason

The bottleneck in OEE improvement plans often lies in manually entering downtime or performance loss reasons. We streamline this process by introducing QR scanner input, ensuring accurate and swift capture of reasons. The scoreboard automatically prompts the line supervisor to scan the reason whenever the line’s performance falls below the target or when a line downtime is detected.

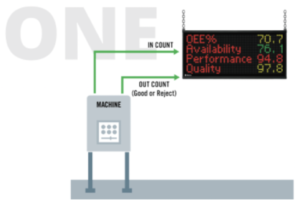

In & Out Count Sensor

Connect one or two sensor inputs from an existing machine, such as a photo-eye, relay, proximity switch, or encoder, to VorneXL.

QR Scanner

Make part run initiation and downtime reason scanning easier for operators by connecting a barcode scanner to XL. Generate barcodes directly from VorneXL for added convenience.

Simple Network

XL can work independently without any IT integration. Let us know if you want it to run on a standalone device yet allow you to access ANYTIME, ANYWHERE.

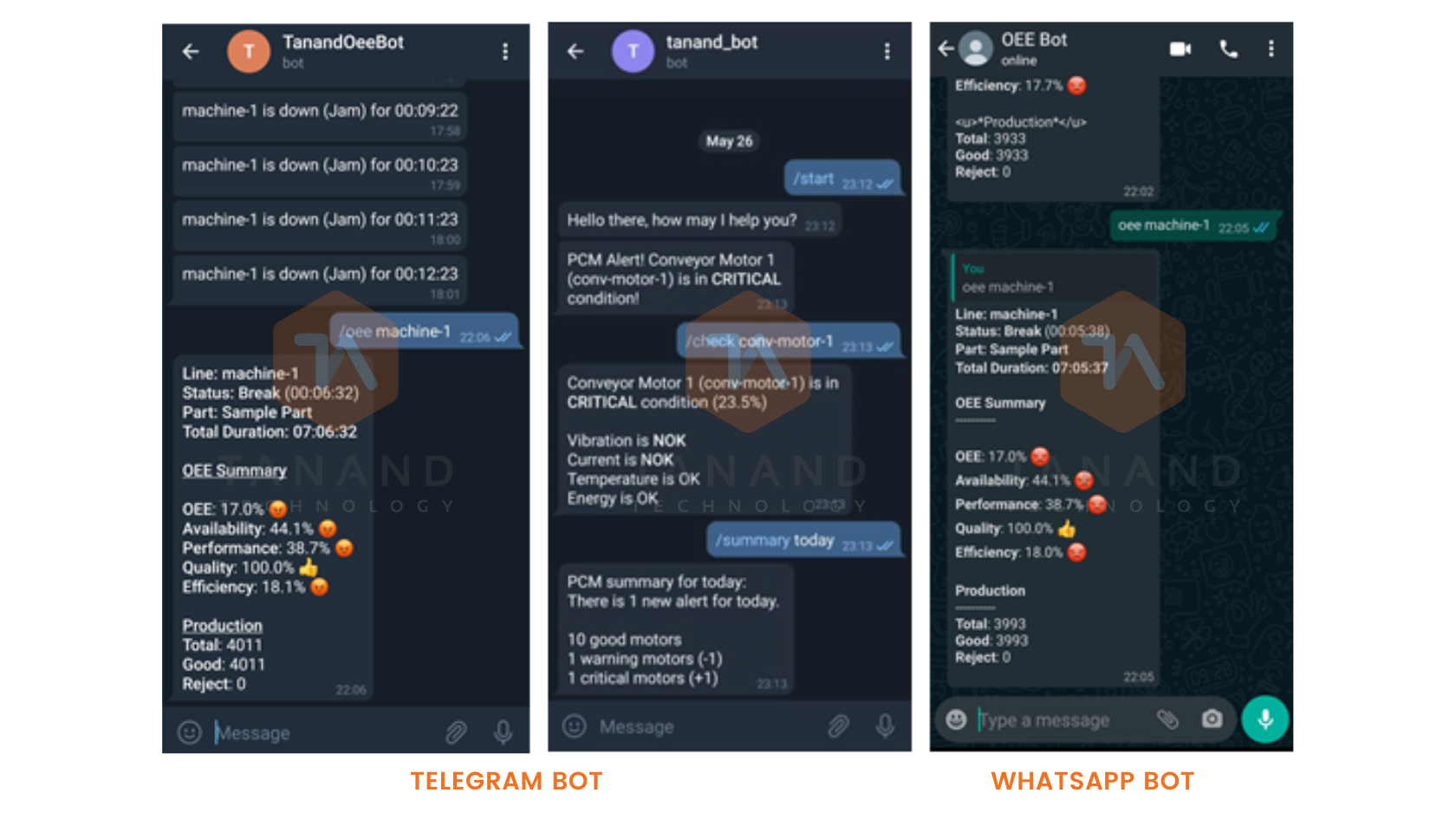

Instant Notification with Telegram / WhatsApp Smart Bot

Receive interactive request and response Analytics Summary Reports, as well as real-time notifications through a Telegram/WhatsApp Bot, accessible anywhere and anytime.