Introduction

Our Next-Gen Autonomous Building Automation System (BAS) / Building Management System (BMS) brings a new era of building automation. Beyond HVAC control, it integrates AI, IoT, Machine Learning, and cloud technologies to manage energy, lighting, security, and more. With a focus on sustainability, energy efficiency, and occupant well-being, this system optimizes building performance while generating automated ESG dashboard.

Implement a comprehensive energy efficiency strategy for your AHU and chiller system, combining data from solar radiation, human occupancy, and thermal load of production equipment , the following steps can be added to the earlier framework. This setup will aim to achieve demand-based control with predictive and adaptive algorithms, improving overall energy efficiency and potentially saving up to 30%:

Data Collection

Solar Radiation

- Gather real-time data from solar radiation sensors to assess heat gain due to sunlight. This directly impacts the cooling load, especially in buildings with significant glass exposure.

Human Occupancy

- Install occupancy sensors in key areas to measure the number of people in different spaces. Occupancy levels directly affect the cooling demand due to body heat and CO₂ levels, which can drive ventilation needs.

Thermal Load of Production Equipment

- Monitor equipment heat output via sensors installed on or near production machinery. Production equipment often generates significant heat, affecting both the cooling load and air quality.

Integration with Predictive and Adaptive Control System

Building Automation System (BAS) / Building Management System (BMS)

- Integrate all sensor inputs into a centralized BAS / BMS or a dedicated controller for your HVAC system. This system will continuously monitor the environment and operational conditions in real-time.

Data Analytics and Machine Learning

- Use data analytics and machine learning algorithms to predict the future cooling load based on historical data, environmental conditions (solar radiation), human occupancy patterns, and the heat generated by production equipment. The algorithm learns from previous trends to anticipate peaks in cooling demand.

Adaptive Set Point Adjustment

Chiller System

- Adjust the chiller’s temperature set point based on the predicted cooling load. When high solar radiation or occupancy is detected, lower the set point to handle the increased load in advance. During low-demand periods (e.g., nighttime or weekends), raise the set point to save energy.

- Integrate variable frequency drives (VFDs) into the chiller system, which can modulate the chiller’s capacity based on actual demand, improving efficiency by reducing unnecessary energy consumption during low-demand periods.

AHUs (Air Handling Units)

- Use the collected data to dynamically adjust the supply air temperature set point. For example, if solar radiation or occupancy is high, the AHU would supply cooler air, while during low-demand periods, it could reduce the cooling effort, improving energy efficiency.

- Implement demand control ventilation (DCV), which modulates ventilation rates based on real-time CO₂ levels and occupancy data, ensuring that only the required amount of fresh air is introduced, further reducing unnecessary cooling and fan energy use.

VFD Control

- Use VFDs to adjust the fan speeds in the AHUs, chillers, and cooling towers based on real-time demand. VFDs save energy by allowing HVAC equipment to operate at variable speeds instead of running at full capacity continuously. For instance:

- When human occupancy and thermal loads are low, reduce the speed of fans, pumps, and compressors.

- Increase the speed when the predicted demand rises, driven by solar radiation, equipment heat load, or occupancy.

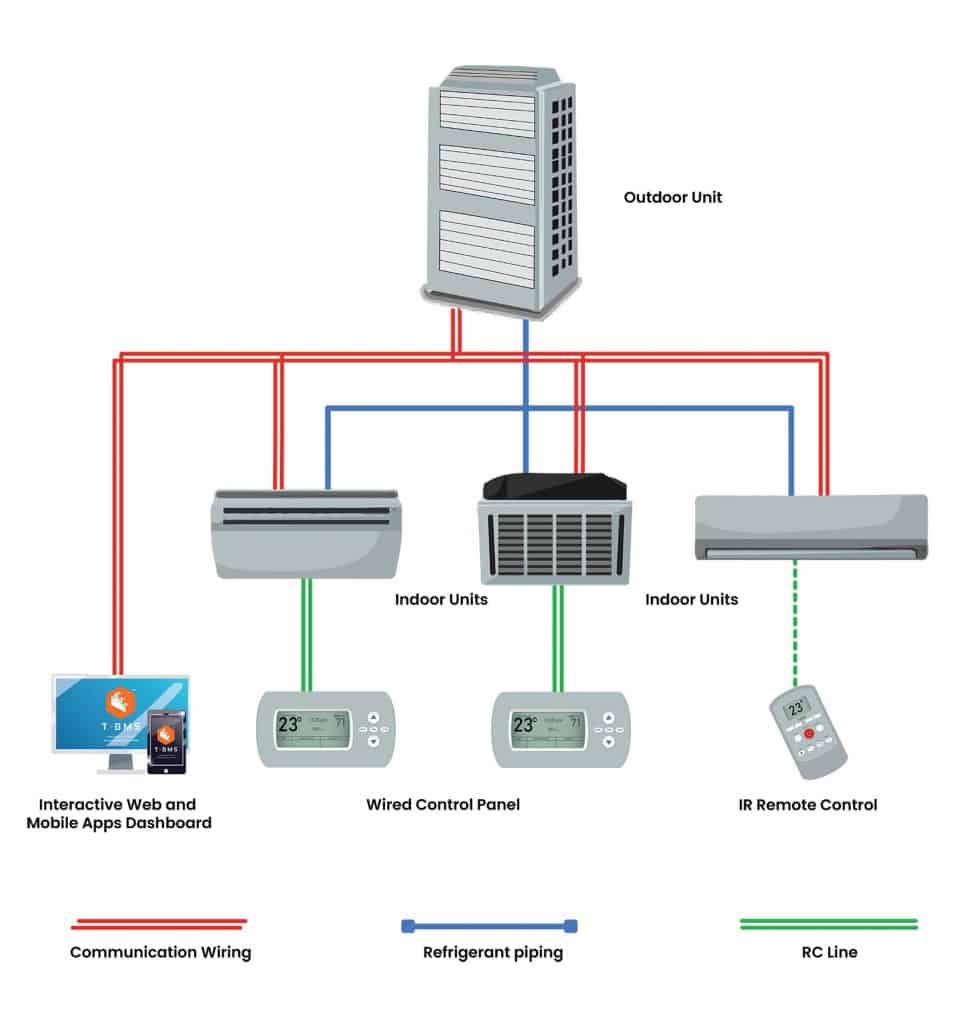

Stand Alone VRF Control System Illustration Diagram

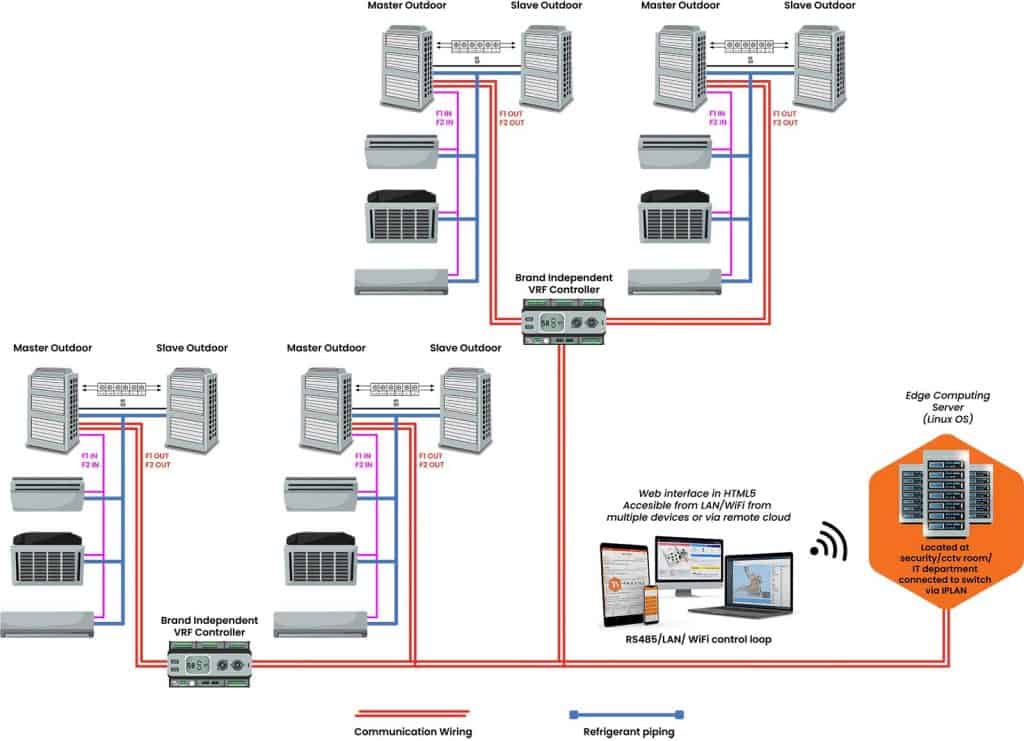

HVAC Optimizer (Easi HVAC) Seamless VRF Integration

Predictive Load Management

- Based on real-time and historical data, the system can predict cooling demand for the next few hours or even days. This allows the HVAC system to operate more efficiently by pre-cooling spaces when electricity is cheaper (demand response strategies) or gradually ramping up equipment instead of rapid starts, which consume more energy.

- Predictive control also helps to prevent system over-sizing or under-sizing by anticipating the exact cooling load needed, preventing unnecessary energy consumption during peak hours.

Energy Efficiency and Savings

CO₂ and Demand-Controlled Ventilation

- Human occupancy sensors and CO₂ data allow the system to precisely adjust the amount of fresh air intake, ensuring ventilation is provided only when needed. This reduces the cooling load by limiting the amount of outside air that needs to be cooled.

Thermal Load Balance

- By dynamically adjusting the AHUs and chiller based on real-time equipment heat output, the system ensures that only the necessary cooling power is used, avoiding overcooling or excess ventilation.

Estimated Savings

- With such a predictive and adaptive system, energy savings can be significant:

-

- Up to 30% savings can be achieved by combining demand-based control ventilation (DCV), VFDs, and smart set point adjustments based on real-time data.

- Peak demand charges can be reduced, as the system better matches cooling capacity with actual needs, preventing overuse of chillers during low-demand periods.

Monitoring and Continuous Optimization

- Continuously monitor the performance of the system and collect operational data. The predictive algorithm can be fine-tuned over time to further improve efficiency.

- Incorporate performance reporting, such as monthly energy savings, to track efficiency gains and justify further investment in automation technology.

By using solar radiation, human occupancy, and thermal load data in an integrated, predictive manner, your chiller and AHU systems can adjust to the specific cooling requirements at any given time, significantly improving energy efficiency while maintaining optimal comfort levels in your facility.

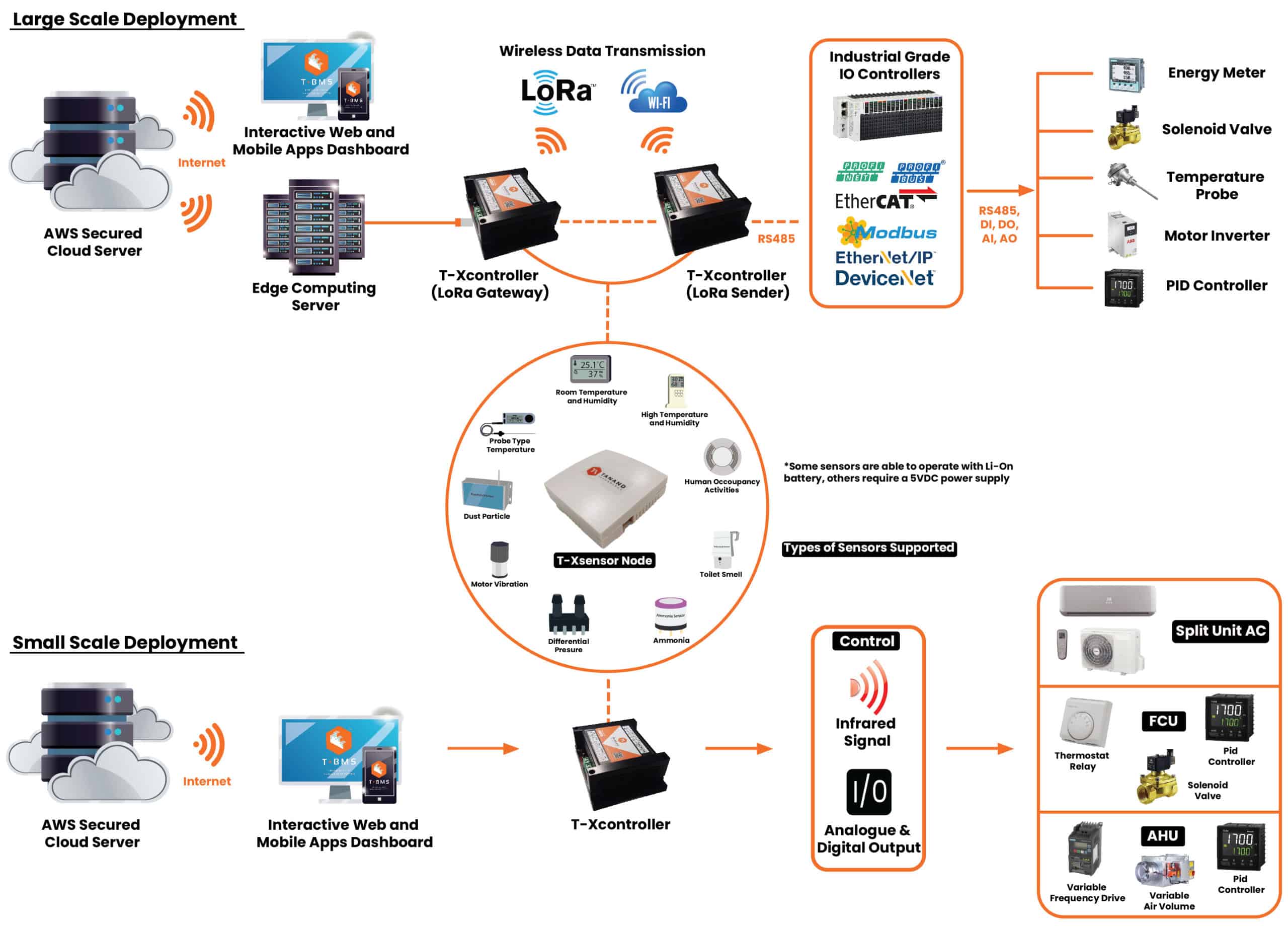

Tanand’s NextGen IoT Edge Controller

Universal DDC with Unlimited Scalability

Supports unlimited I/O points (AI/AO/DI/DO) through modular plug-in modules, allowing for versatile and expansive control solutions.

Rich Protocol Support for Seamless Integration

Comes with over 200 field-proven OT protocol adapters, including Modbus, OPC UA, MQTT, and more, ensuring compatibility and connectivity.

Robust & Reliable Hardware Configuration

Powered by dual Cortex-A7 @1.2GHz processors, 512MB RAM, with RTC, Dual LAN ports, RS485, and RS232 connections. Certified by CE/ROHS/FCC and designed for harsh industrial environments with operating temperatures from -40 to 85°C.

Powerful Open-Source Programming Interface

Features an intuitive, visual programming interface that is open-source, enhancing adaptability & future support without licensing fees.

Industry-Leading Durability and Protection

Built to withstand industrial challenges with anti-static, anti-surge, and anti-reverse power protection. Includes a 5-year warranty against manufacturing defects.

How Do We Optimize & Integrate Your Existing Centralized & Split Unit Air-Conditioning System

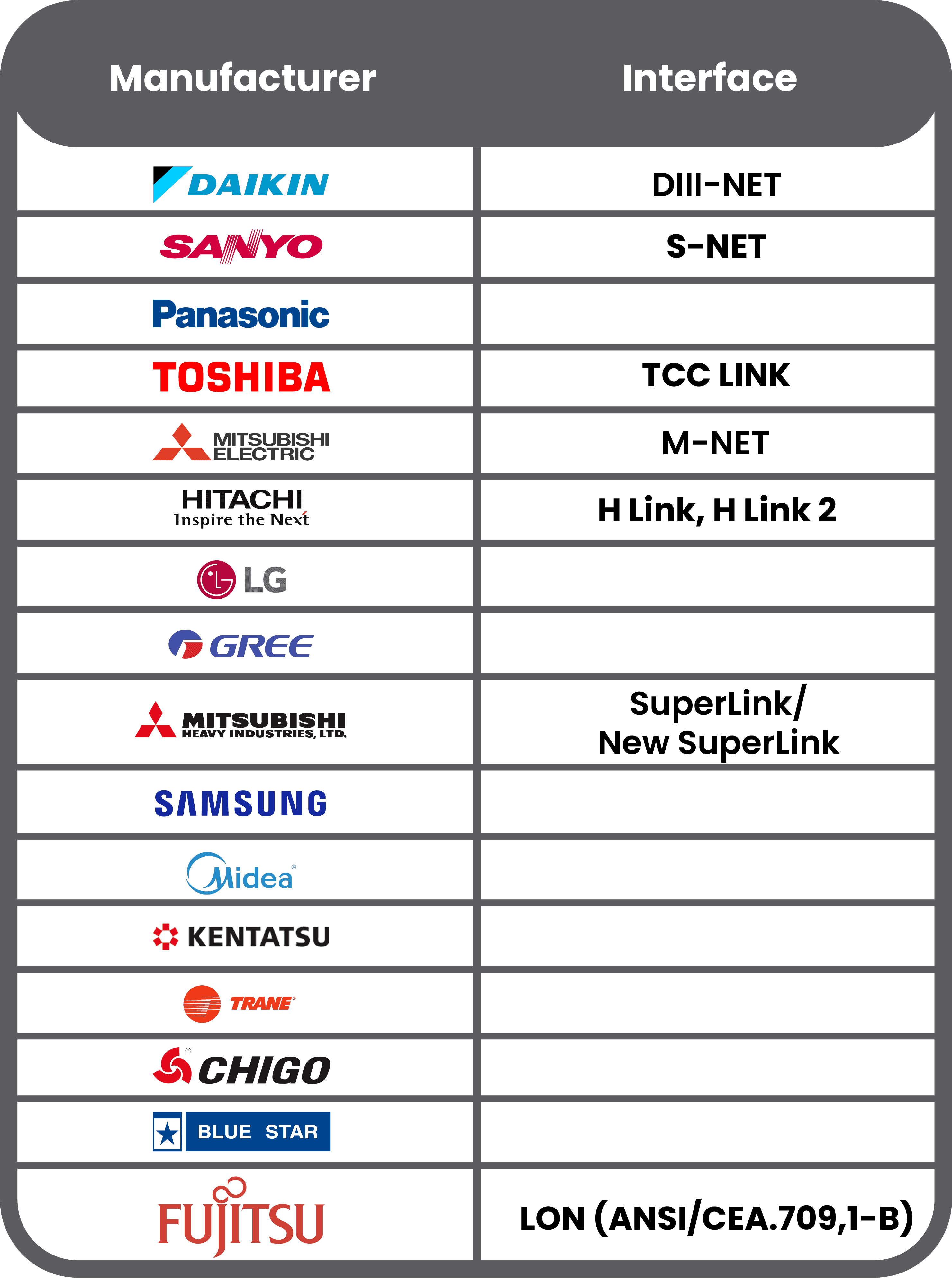

Works with Various VRF Brands, Interface & Parameters Without Any Hardware Changes

Remote control parameters for indoor units that are supported:

- On/Off

- Cool/Auto/Dry Mode

- Fan speed

- Set temperature

- Swing

- Filter sign

- Malfunction code

- Remote troubleshooting

* the existing indoor wired controllers will remain functional after the integration

Already Have BMS/BAS System?

We are compatible with leading platforms and systems. Avoid duplication, high capital expenditure and achieve the fastest ROI.

Having multiple BMS platforms supporting multiple chiller types and AHUs?

We offer cost-effective way to synchronize all your HVAC systems into single platform with the capabilities of remote monitoring through smart devices and providing real-time alerts with historical trend.

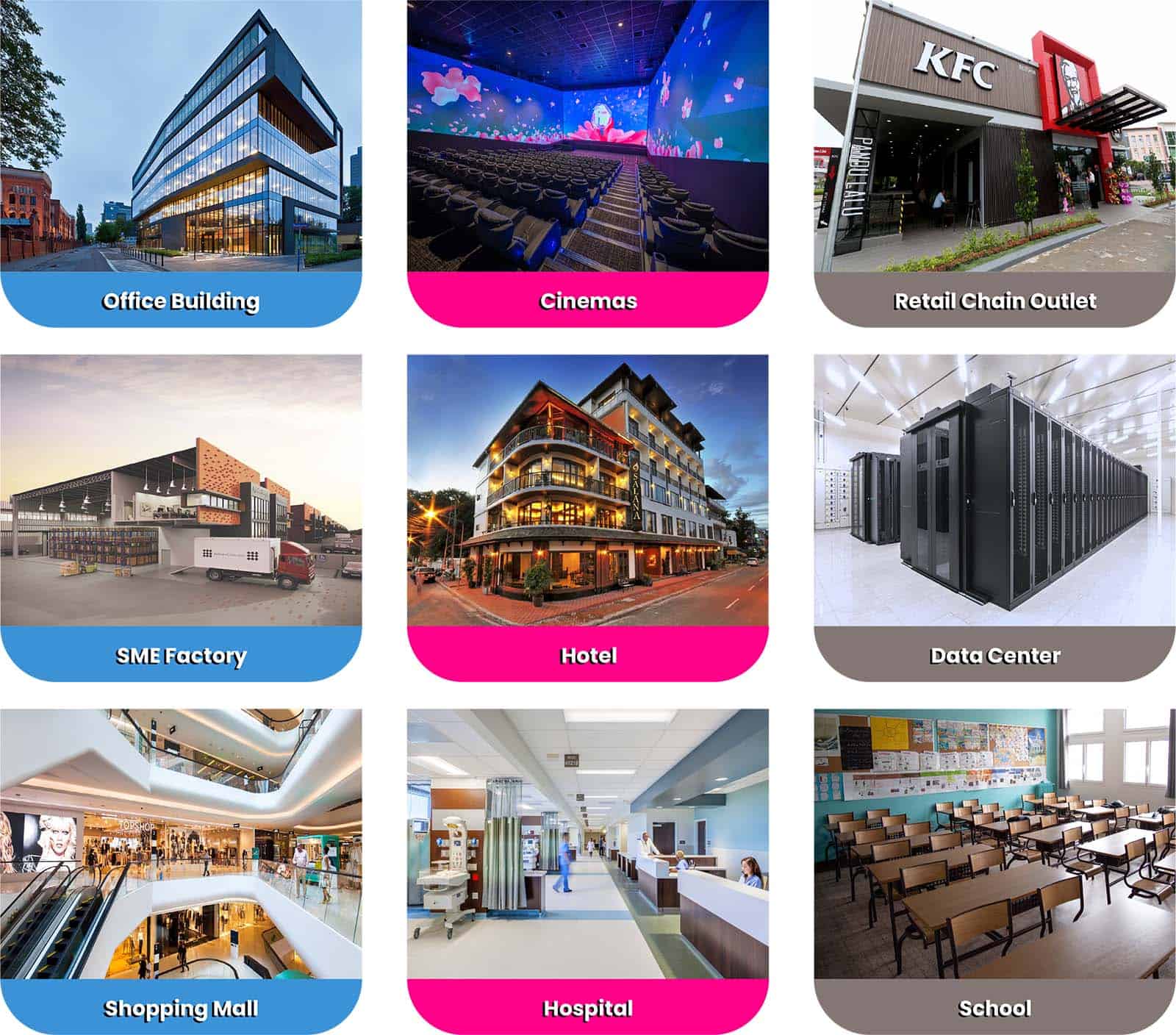

Scalability & Seamless Integration

This solution is scalable to fit buildings of any size or complexity, from single-site operations to large portfolios. Its open architecture allows integration with legacy systems, enabling centralized control for multi-site businesses.

- Modular Design: Add or remove components as your building’s needs evolve, ensuring the system grows with you.

- Hybrid Cloud-Based Management: Utilize cloud infrastructure for enhanced scalability, data storage, and remote access capabilities.

- API Integrations: Connect with third-party applications and services through robust APIs, expanding the functionality of your BMS.

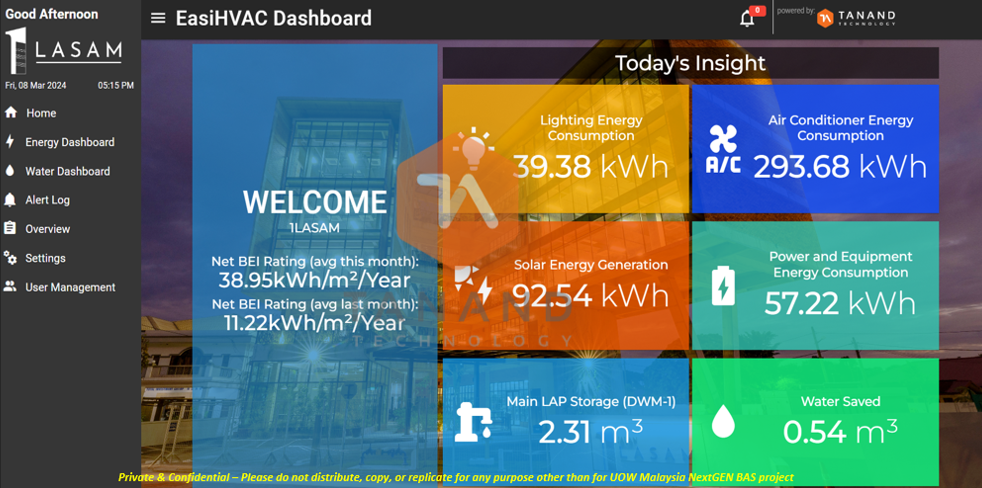

Sustainability & ESG Reporting

Sustainability is integral to our BMS, which not only optimizes energy usage but also provides comprehensive ESG reporting to help you track and achieve your environmental goals.

- Automated ESG Dashboard: Generate detailed monthly reports on energy consumption, carbon emissions, and other sustainability metrics.

- Regulatory Compliance: Ensure adherence to local and international sustainability standards and regulations with accurate, real-time data.

- Sustainability Dashboards: Visualize your building’s environmental performance through intuitive dashboards and analytics tools.

Address Specific Needs From Multiple Stakeholders

Top Management

“How can my building operate sustainably, green, and efficient?”

Finance Team

“I want an overview of where the money is going and which area I can save on OPEX while improving efficiency.”

Facility management companies/building manager

“What is my real-time building problem and how can I reduce complaints without increasing manpower?”

Employees

“I need a comfortable working environment that will make my daily work easy and efficient”

Our Success Stories

- Smart scheduling with web management console

- Android & iOS app to ease building operator

- Environmental monitoring & integration

- Multi-level data monitoring with end users control options

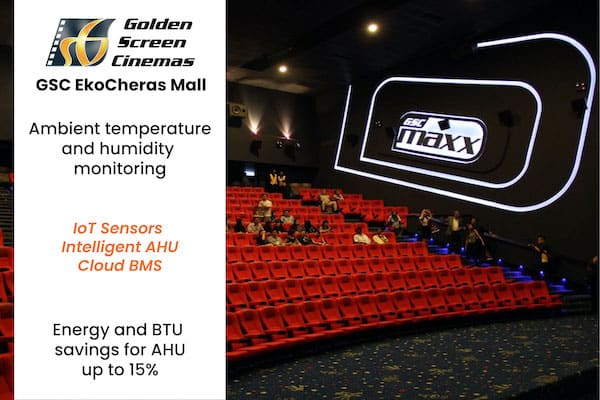

- Real-time ambient temperature & humidity monitoring couple with energy management

- Smart thermostat with chilled water valve control

- Starter panel automation

- Smart scheduling of AHU

- Intelligent AHU resulted in energy and BTU savings

- Real-time Chiller Plant Efficiency Measurement kW/hour

- Real-time Chiller Plant Load (RT)

- Real-time Chiller Performance Benchmarking

- Real-time Demand Control Optimization (Air side/AHU side) with 10X real-time accuracy feedback

- Real-time Chiller Plant Optimization (Remote Set Point, Scheduling & Part Load Optimization)

- Real-time abnormalities detection (from load changes, efficiency changes, temperature changes, or energy pattern changes)

- Insightful, data trending, monitoring & operational control all-in-one dashboard

- Real-time room occupancy detection for energy saving with smart thermostat

- Smart light relay control using Tx-Human Activity Sensor

- Total 258 rooms

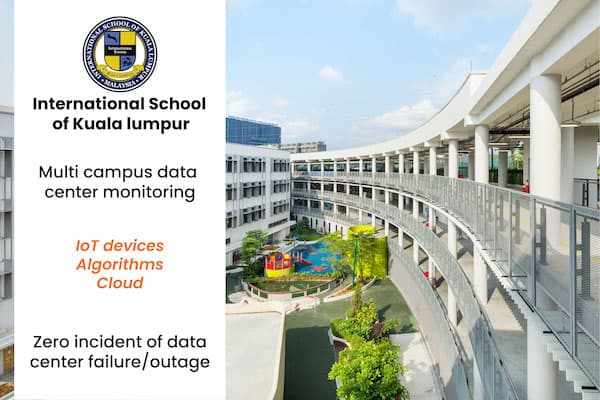

- DCIM solution to monitor environment factor for each server rack

- Track energy usage with power quality of each rack

- Real-time performance & equipment monitoring at multi campus via smart devices

- Instant alert notification when there is abnormal behaviour

- Real-time temperature & humidity monitoring

- Track energy usage of each outlet while optimizing indoor temperature based on real-time demand

- ACMV energy saving logic based on real-time environmental factors

- Cost saving while still maintaining food quality and guest comfort