FEBRUARY 28, 2024 | MAINTENANCE EFFICIENCY, EARLY FAULT DETECTION, DATA ANALYTICS, MACHINE LEARNING, MEAN TIME TO REPAIR

Introduction

In the fast-paced world of industrial maintenance, staying ahead of equipment failures is crucial for minimizing downtime and maintaining efficiency. EasiPCM, a cutting-edge system powered by IIoT (Industrial Internet of Things) data analytics and machine learning, is transforming how businesses approach equipment maintenance. This innovative system not only simplifies the maintenance lifecycle but also significantly reduces Mean Time to Repair (MTTR) and overall downtime.

The Challenge of Unexpected Downtime

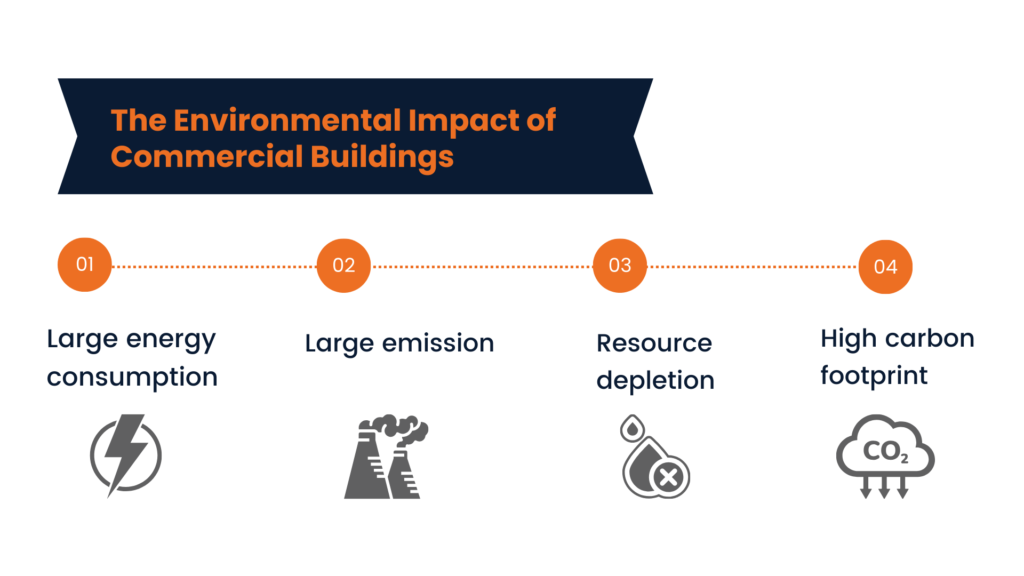

The cost of unplanned downtime in critical machinery can be significant. Traditional maintenance strategies often fall short, leading to costly, inefficient reactive maintenance.

Tanand EasiPCM: A Holistic Predictive Maintenance Tool & Simplified Maintenance Lifecycle Management

Tanand EasiPCM AIoT offers a comprehensive solution that goes beyond mere fault detection. It integrates a lightweight CMMS, leveraging real-time data for effective maintenance management, thus minimizing downtime and extending machine lifespan.

EasiPCM also employs automated reminder alerts. These alerts are conveniently delivered via Email or EasiBot, an Assistant ChatBot designed for seamless communication. Additionally, the system is capable of automating Work Order Creation through API integration with your existing Computerized Maintenance Management System (CMMS). This feature streamlines the maintenance process, reducing manual workload and enhancing efficiency.

Advanced Early Fault Detection with IIoT and Machine Learning

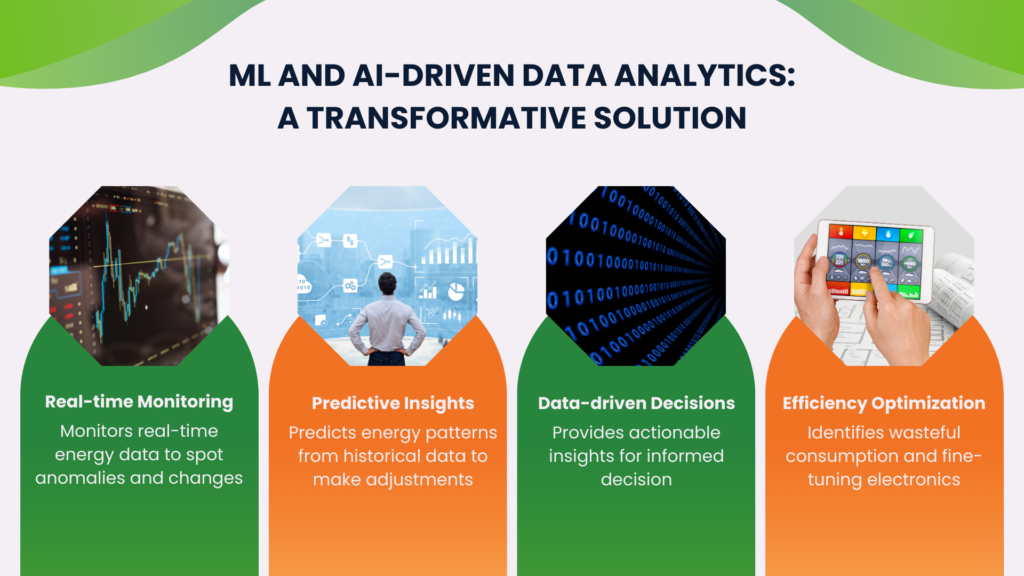

The optional integration of IIoT sensors with machine learning-based data analytics elevates EasiPCM’s capabilities. This combination allows for multi-dimensional comparisons between historical trends and live data streams. The result is an advanced Early Fault Detection (EFD) system that alerts users to potential issues before they escalate. By accurately predicting equipment failures, EasiPCM drastically reduces the time spent on downtime management.

- Data-Driven Maintenance Decisions: Utilizing actual machine runtime data, service intervals, and predictive health scores, Tanand EasiPCM AIoT facilitates timely and necessary maintenance activities.

- Comprehensive Monitoring: The system integrates various data sources, including alarm and event logs, and inputs from AIoT sensors like vibration, temperature, noise, and spikes, for a complete understanding of machine health.

- Efficient Predictive Maintenance Scheduling: Its automated, data-driven approach refines preventive maintenance into predictive maintenance schedules, ensuring maintenance activities are neither excessive nor inadequate.

- Just-In-Time Maintenance Approach: This approach minimizes unnecessary interventions, reducing downtime and maintenance costs.

- Spare Parts and Supplier Analytics: Deep insights into spare parts lifespan and supplier performance enable informed decisions, enhancing reliability and reducing costs.

Optimized Operations and Maintenance

EasiPCM is not just about early fault detection; it’s about optimizing your entire maintenance strategy. The system addresses the common challenges of over-maintenance and under-maintenance faced by facility maintenance teams. Whether running a building or a production manufacturing plant, EasiPCM enables teams to operate more efficiently. By minimizing unnecessary maintenance while ensuring critical issues are addressed promptly, EasiPCM ensures that your operations run smoothly and without interruption.

Conclusion

Tanand EasiPCM AIoT represents the future of industrial maintenance. By combining AIoT with advanced data analytics and seamless integration capabilities, it offers a powerful solution for predictive maintenance. Adopting this technology means embracing a more reliable, efficient, and cost-effective approach to machine maintenance.