SEPTEMBER 15, 2021 | REAL-TIME LOCATION SYSTEM, LOCATION SYSTEM INSIGHTS, AUTOMATION INSIGHTS

As digitalization and automation are the trend-setting developments surrounding industry 4.0, it is essential to adopt a centralized intelligent system to help improve and sustain the work of humans and machines.

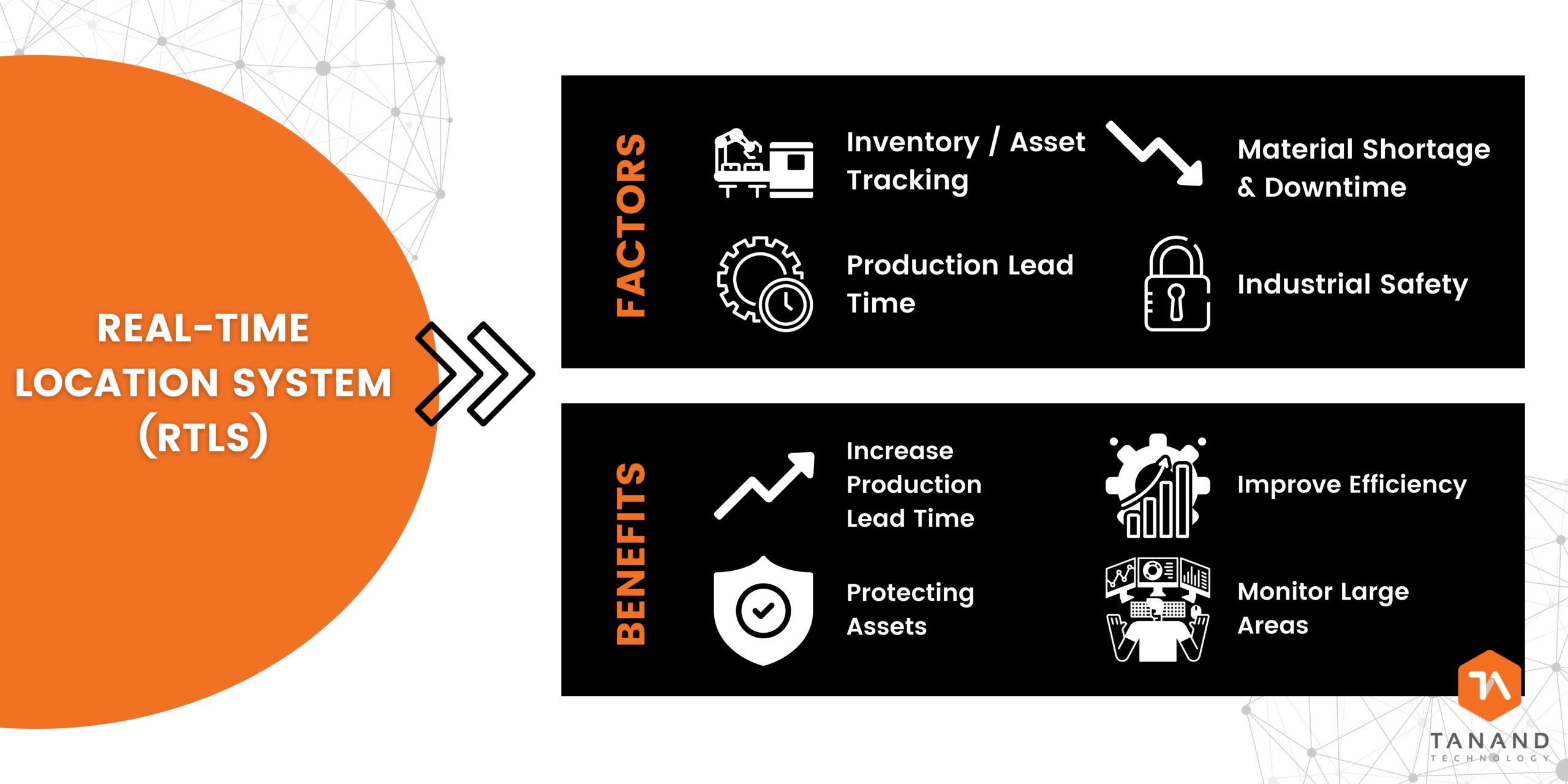

A real-time location system (RTLS) is one solution that has received much attention to be a cost-efficiency solution. It has made a significant contribution to the overall industrial environment, but how does the implementation of RTLS significantly contribute to your industrial environment?

There is a critical ingredient to success when it comes to efficiency improvements: data.

An effective industrial environment is more of a guessing game than an intelligent and efficient operation without real-time data. The decisions you make would not be known if they had a good impact until weeks or months after the changes were implemented. This is where RTLS eliminates the assumed factors of your operation by delivering quick real-time data of your industrial environment.

Inventory/ Asset Tracking

Keeping track of critical assets/inventory is crucial for your manufacturing factory. Manufacturing pieces of equipment is essential for the company, and they are considered an expensive asset that needs to be maintained and located at all times. Inability to track your assets/inventory can disrupt the company production efficiency and production line.

Production Lead Time

In a conventional factory, workers must pick and pack assets by searching through racks and shelves, sometimes spending a longer time when certain assets are misplaced. When manual asset recording processes are used, it is more prone to errors with time delay because assets are usually not recorded immediately when it reaches the warehouse.

Material Shortage and Downtime

When a material run-outs at any production station, it causes a line stop and loss of productivity. It takes time for workers to respond to them and this also results in coordination breakdown.

Industrial Safety

Globally, industrial safety is becoming more critical, with government and regulatory bodies enacting higher safety standards that businesses must comply with. At times, manual staff tracking and accountability are highly inaccurate during emergencies. Moreover, the process is also time-consuming, and due to industrial sites typically in a large area and workforce, it is impossible to act urgently.

The benefit of RTLS:

- Protecting assets and equipment with real-time information

- Increasing production lead time by accurately locating assets and recording necessary asset data quickly

- Improving efficiency between production workstations and monitoring work in progress

- Monitoring a large area of industrial environment activity to monitor workers’ safety and hazardous area

RTLS Technology (BLE/ Active RFID/UWB)

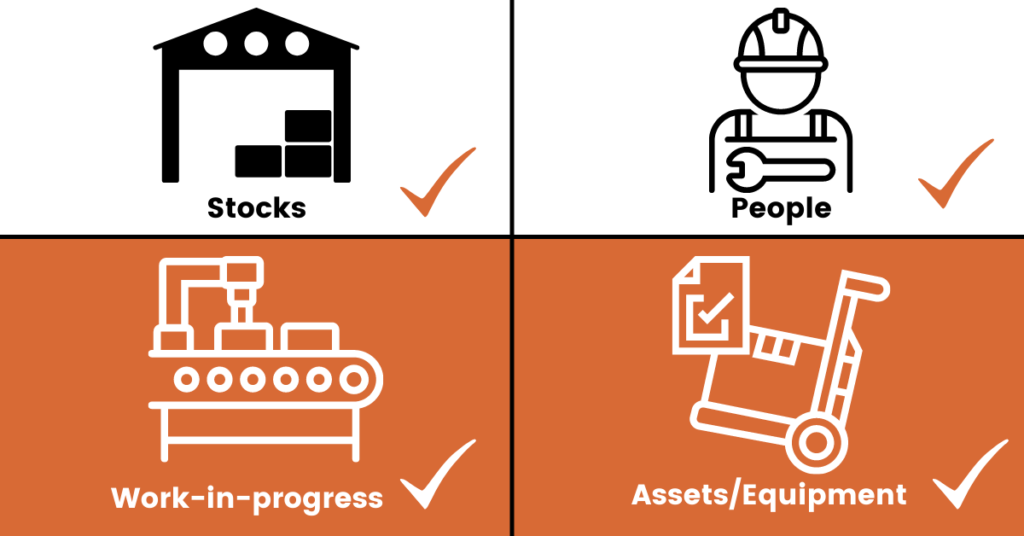

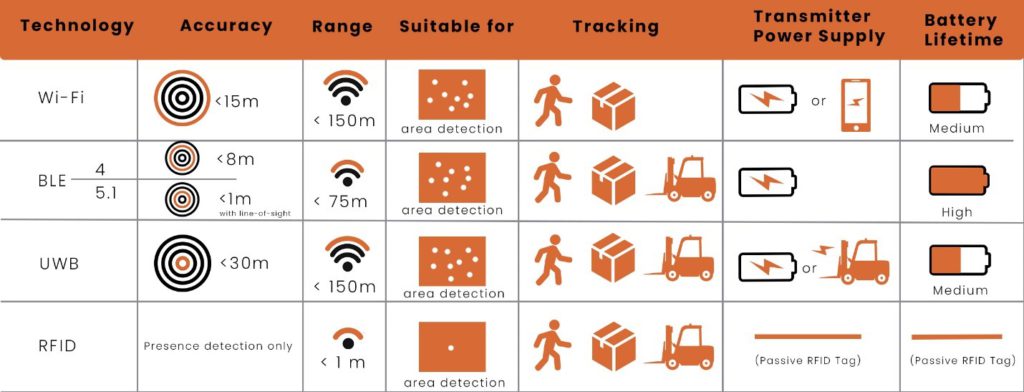

RTLS configuration varies widely depending on the type of facility in which the technology is employed. With various components of RTLS technology such as Bluetooth Low Energy (BLE), Active RFID, and Ultra-wideband (UWB), it sends the data signal to the server to determine the location of the devices. Each component varies in ranges, accuracy, and battery lifetime to suit the industrial environment.

The choice of the most suitable technology depends on several factors:

- (Precision) requirements for the system

- The conditions on site

- The number of assets to be tracked

- Budget

Ready to implement an RTLS solution in your industrial environment? Kindly refer to the video below for more information, and contact us for a private e-meeting to start your RTLS journey, we are happy to help you to choose the right technology for your project.